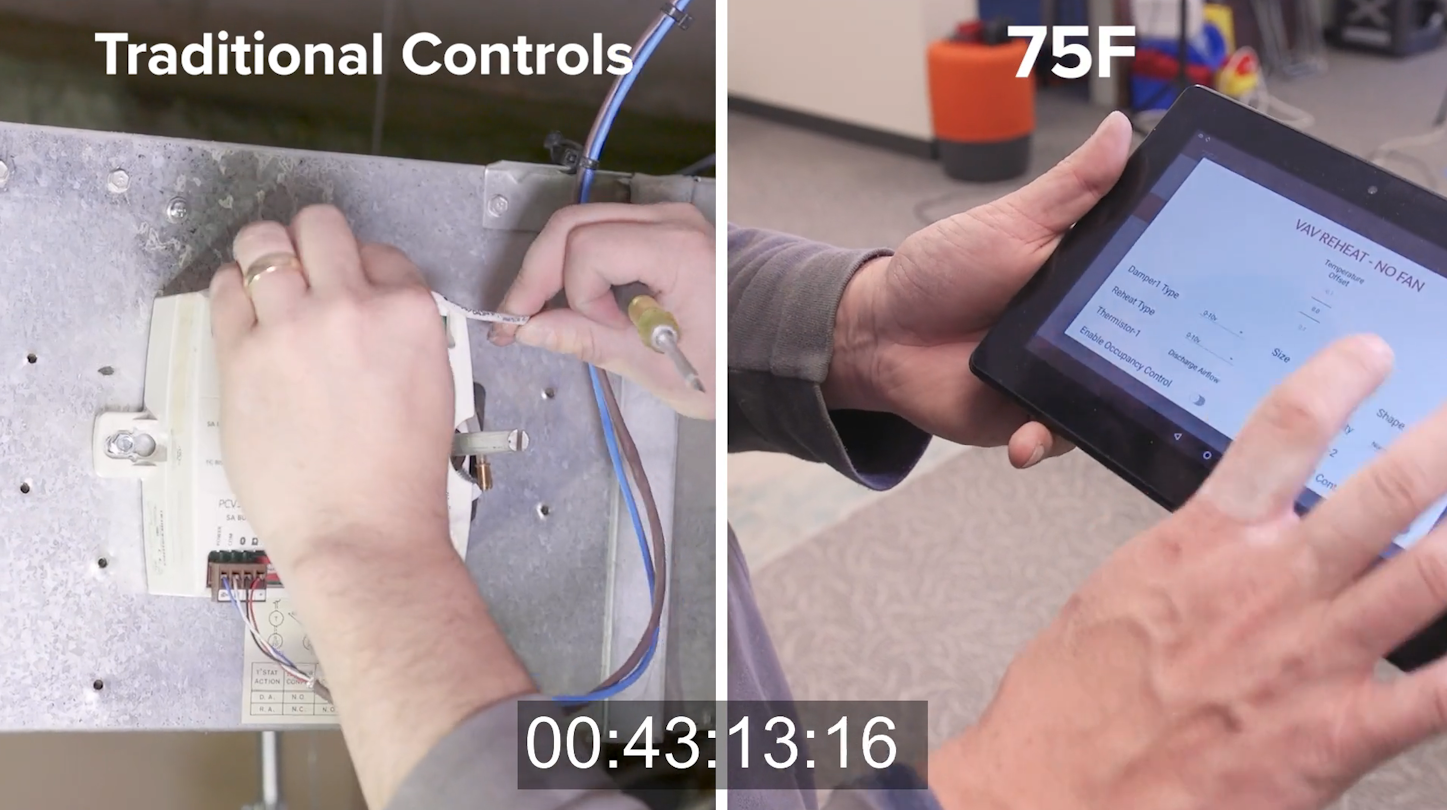

Time & Motion: 75F vs Traditional VAV Installation

In the time it takes to install, program, and network one VAV box with a traditional building controls system, a contractor could install, program, and network four VAV boxes with 75F product and still have time for lunch.

Sound like an audacious claim? It is. But it's also true.

75F recently put our IoT-based Building Management System (BMS) head-to-head with a traditional commercial controls system by hiring an independent installer to install each system on the same VAV box here in our Minneapolis headquarters. The installer has 13 years of experience with traditional building automation, and aside from our standard online training course, no experience installing the 75F system. The traditional controls system took three hours and 30 minutes. Installing 75F took 45 minutes.

With no need for communications wiring, VAV programming, or manual commissioning, installing 75F is radically intuitive and rises to the cloud-enabled standards of today. In this video, we show both installation experiences side by side to demonstrate how the IoT approach to commercial building management makes a difference at the installation stage.

The Traditional Way: 3 hours, 30 Minutes

Commercial building controls have an established reputation for complexity. Most control systems today have technological origins in the 80s and 90s, when a flurry of direct digital controls, BACnet protocol, and platforms like the Niagara controls framework came online.

Despite the digital boom of the early 2000s and on, our commercial buildings’ control systems still largely require deep and specialized product knowledge for program selection, laborious commissioning, local software maintenance, and long, frustrating installations — all for controls systems that can’t deliver what most people expect out of the cloud-connected world in which we live.

Considering the technological limitations of traditional systems, here are the steps required for this type of VAV installation:

Step 1: Pull BACnet wire

Total time: 24 minutes

Step 2: Mount the VAV controller and pull thermostat wire

Total time: 13 minutes

Step 3: Terminate wires to the VAV

Total time: 8 minutes

Step 4: Connect air flow sensor

Pneumatic tubes were incorrectly sized, and this needed to be rectified

Total time: 20 minutes

Step 5: Install thermostat

Total time: 22 minutes

Step 6: Program the VAV

Start PC and local software program

Plug in communication device

Establish connection to controller

Create control program

Confirm i/o connections

Confirm sensor scaling

Push program to controller

Disconnect communication device

Total time: 18 minutes

Step 7: Commissioning

Start engineering software

Discover devices on communication bus

Add device to network

*License expansion issue encountered; real-world wait time from two hours to two days

Discover points within the device

Add points to the database

Build VAV graphic

Total time: 1 hour, 48 minutes

The traditional BAS’ structural weaknesses are especially apparent in the first and final two steps. Not only are the steps labor intensive, some of them rely on external parties to function properly. Encountering an issue like a license expansion is common in the field. In the real world, the installer would need to contact their distributor, who would then contact the manufacturer via an online form or by phone. Meanwhile, the installer cannot proceed until the expansion is granted. Wait times vary depending on how many requests are in the distributor’s queue, and then how many requests are in the manufacturer’s queue. Results can take up to two days.

Where traditional automation is manual and complex, an IoT-based system is automatic and intuitive.

The 75F Way: 45 Minutes

The IoT-based approach to building controls turns the norm on its head by integrating cloud connectivity from the ground up. With devices that communicate over a proprietary 900 MHz wireless mesh network, auto commissioning and pre-programmed sequences of operation designed to follow industry standards like ASHRAE Guideline 36, the IoT method drastically cuts down install, programming, and networking time and complexity while maintaining sophisticated system capabilities and integrity.

Here are the steps required for a 75F VAV installation:

Step 1: Mount the actuator

Total time: 5 minutes

Step 2: Wire actuator to 75F® Smart Node™

Total time: 4 minutes

Step 3: Install discharge air temperature sensor

Total time: 7 minutes

Step 4: Pull wire to the space temperature and humidity sensor

Total time: 11 minutes

Step 5: Pull room sensor wire down through wall and install sensor

Total time: 13 minutes

Step 6: Pair the Smart Node with the 75F® Central Control Unit™ (CCU) and return tablet to CM

Select device type on CCU

Select applicable sensors on CCU

Select ranges on CCU

Total time: 5 minutes

The most noticeable differences in 75F’s VAV installation are the lack of BACnet or communications wiring and drastically reduced commissioning and networking time.

The commissioning step may appear simple, but there’s a lot happening in the background — once the installer makes all necessary selections at the CCU, the controller is automatically added to the comm network, building network, and the cloud, and is already remotely accessible through 75F’s user portal, Facilisight. Even more, our system has created alerts, started trending data, and auto-commissioned the devices to run as well as possible.

All of this happens in just five minutes. Manufacturers across the industry may strive to reach this reality one day, but 75F has achieved it. The future of control is here today — and fast, lightweight commissioning is only a single facet of the deep-reaching ripple effect IoT creates when applied natively in building management.