How are Digital Twins used in Building Automation?

What is a digital twin?

Let’s start with a definition: A digital twin is a virtual model of a real-world object or space. It can be a digital replica of an object in the physical world, such as a jet engine or wind farms, or even larger items such as buildings or even whole cities. Within the built environment, a digital twin is a digital or a web-based representation of a physical building, system, or sequence, scaling all the way up to a city or utility grid. A digital twin can represent everything within a building and can offer real-time data about how those assets are performing.

Digital Twins have two primary uses:

Visually displaying real-world data in a representative or structured way, such as from sensors or equipment.

Simulating data to predict how systems or processes will perform.

Both digital twin uses can involve very large data sets, and in addition to analytics and tools for visualization, both rely on the internet of things (IoT), machine learning, or artificial intelligence (AI) to enhance the output, process, or service.

Advancements in data analysis and optimization — as well as open systems like Project Haystack for structuring and organizing building data — have made digital twins a critical pathway to drive innovation and improve performance in the built environment.

Origin of the digital twin

David Gelernter described in detail the concept of using computers to create a digital copy of the physical world in his 1991 book, “Mirror Worlds.” Thirty years later, this remains an easy way to understand the digital twin’s value to buildings and their operators. Michael Grieves of the Florida Institute of Technology and the University of Michigan would go on to take the digital twin idea further, outlining a wide array of manufacturing and production design benefits from digital copies of factories and industrial buildings.

However, the term “digital twin” itself came not from industrial production, but from rocket production. NASA’s John Vickers coined the phrase in 2010 to refer to ultra-realistic simulations of space capsules that could be designed, modeled, and tested without the cost and risks of actual launches.

In 2017, Gartner named the term “digital twin” as one of the world’s top 10 most important strategic technology trends, and digital twins have been used in an ever-growing array of real-world applications and processes, from the strategy of Formula 1 racing teams to metal fatigue and corrosion resistance in the design of large offshore wind turbines.

In short, digital twins are an important technological innovation, and the concept of a digital twin is important especially when merging physical systems like buildings with digital systems and software applications like building analytics, building optimization, or building troubleshooting software and applications.

Digital twins in smart buildings

Buildings contain a growing array of complex mechanical devices and equipment, sophisticated systems and sequences, and suites of features to improve the safety, comfort and productivity of occupants. To monitor and control a modern building requires some level of interoperability and machine-to-machine communication, sometimes of disparate systems and equipment. It also requires understanding a large amount of data.

Digital twins provide an intuitive way to store, organize, and access the big data generated by these complex building systems. Building Management Systems that incorporate a digital twin can create significant value for asset owners, managers and occupants by making data once buried in proprietary systems and controlled by equipment manufacturers accessible and intelligible to everyone.

The value of a digital twin as a platform

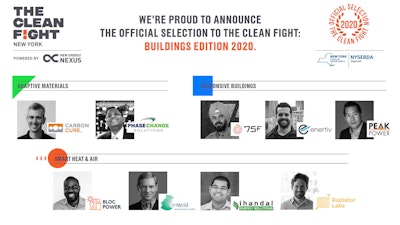

At 75F, we believe building management systems should be contextually integrated.

This is different from many smart building software applications that pull data from one or more siloed systems in the building (energy meters, indoor air quality sensors, or occupancy counters) and essentially provide an application or analysis that leaves the data in a new and unique silo, with a new and unique data model. These highly specialized and narrow applications make it difficult to switch between applications or gather context and information — is poor air quality readings in a conference room linked to high occupancy, lower ventilation, or something else?

This friction can be addressed by removing building data from silos and implementing a digital twin as a standardized and enterprise-level view of disparate systems across not just a building, but a building portfolio. By bringing building data into a digital twin in a structured way, that building data can be used in a variety of ways:

Data from a digital twin can be shared in APIs for analysis by any third-party tools

Digital twins can be operationalized with new or more sophisticated sequences or processes

Digital twins can be simply used to clean data for quick integration into dashboards or other building intelligence tools

Without a digital twin, integration to disparate systems often requires a slower and more costly custom integration. It also may be less useful: Analytics solutions may monitor what building data in a particular silo or even series of silos is doing, but without the full context or integration across multiple building systems, these tools can’t deliver a why.

Where applications are built on whole-building data from a digital twin or share a common structure and tags across disparate systems, they can natively and contextually integrate with each other.

How can a digital twin be used in a building?

This can be understood using an example of a digital twin in a building’s HVAC chiller plant. Instead of an analytics application showing performance below a benchmark, having building data in digital twin can bring contextual integration and a much greater degree of optimization.� In many buildings, these chilled water systems offer tremendous potential for energy savings. This must be done while meeting the thermal comfort needs of occupants.

In this example, we can imagine several levels of value:

First, connecting systems and equipment in a digital twin brings those systems—In this case a chiller unit—from a basement, maintenance room, or crawlspace into any web browser. Sometimes these devices are parallel or series units. Some have advanced water-side economizing and some do not. There is still more variation in chillers with dedicated or headered pumps, variable-primary or primary-secondary loops, and constant or variable speed condensers. All this data needs to flow into a digital twin to understand and control these devices, or integrate them into a digital twin.

Second, machine learning algorithms or pre-programmed software sequences can leverage connected system or equipment data in a digital twin to vary the pumping capacity of the chiller system to match the required thermal loads and adjusting airflow accordingly. Data from each floor and zone served by chilled water equipment is structured in a digital twin with the set temperature, humidity, or ventilation requirements of those zones in order to not only optimize waterside systems, but visualize how and why those optimizations are occurring. This represents a responsive optimization in which the chiller plant “chases” the setpoints of a space.

Third, an even greater degree of savings can come from predictively and proactively anticipating the needs of a building and adjusting pumps and fans accordingly. This might mean taking system and equipment data in a digital twin and adding in third-party weather forecast data, any programmed tenant schedules from an outside tenant management app, thermal building performance history zone by zone via temperature sensors throughout a space, or real-time sensor data about occupancy, all merging with data from pump sensors and delta-T performance of the specific building system to make the most effective use of chilled water, as dictated by ASHRAE Standard 90.1 and the International Energy Conservation Code.

A digital twin may not be able to directly help a building manager or facilities engineer identify the chillers, cooling towers or pump sequences, optimizing start times or differential pressures required to optimize a chilled water system, but a digital twin can structure data from this equipment in a platform such that other applications can deliver these improvements and savings.

Where a facilities technician receives a hot or cold call, the digital twin can show active alerts on a particular piece equipment, the status of preventative maintenance on a fan or air handler, historical trends about the occupancy or humidity of a space, and all this data can be in a single, contextual place.

The digital twin challenge in outdated systems

Some of the systems found in buildings, such as HVAC, lighting, visitor management, or access control systems, were never intended to be integrated but are capable of delivering great value when brought together.

For example, imagine the use case of a 75F customer in Singapore. Several floors of a large, multi-use high-rise building were retrofitted for a new micro-coworking space. Members can present a card to an access control system connected to a visitor management and badging software and receive a room assignment for business meetings, work, or quiet study or recreation. Lights and ventilation in assigned rooms come on as doors unlock and members badge out, alerting staff to clean and disinfect the space for the next member. Additional integrations to track frequency and duration of visits, as well as energy consumption and profitability by location in a single-pane-of-glass view of building performance, were desired in later phases of the project.

In this digital twin use case, a customer faced a challenge shared by many buildings and facilities owners: affordably and successfully integrating existing, disparate systems. Time to deployment was critical, as leasing costs and the co-location model itself required bringing the building online.

This trouble in syncing up systems goes deep in the building world, even down to individual equipment within an overarching HVAC system. We can break down the reasons behind this integration challenge into four common categories:

Proprietary: Not adhering to industry standards for integration, control, and operation.

Monolithic: All cloud-hosted components are one giant application.

Platform-specific hosting: Runs only in specific platforms.

Closed system: Not open to integration from other applications.

These problem areas, when combined, present specific challenges when considering the digital twin and holistic HVAC system operation:

Closed system + platform-specific hosting + proprietary = difficult to integrate.

Monolithic + platform-specific hosting + proprietary = difficult to maintain.

Closed system + monolithic + platform-specific + proprietary = difficult to test.

Monolithic + platform-specific = difficult to scale.

How 75F makes the digital twin possible for more buildings

75F leverages a flexible, IoT-based system architecture to address and bypass the outlined challenges.

Where traditional buildings have proprietary systems that don’t adhere to industry standards, 75F is built on a flexible foundation that adheres to current and emerging industry trends — Haystack and BACnet, for example — and best practices, such as ASHRAE GPC 36, and more.

Where traditional systems are monolithic, 75F is modular with smaller, business-driven components that make flexibility easy.

Where platform-specific hosting is common in many buildings, 75F is containerized and platform agnostic. This means that 75F’s components can operate inside containers that run anywhere, from a local laptop to a customer’s on-premise server environment.

And finally, 75F’s platform focus with Application Programming Interfaces (APIs) means 75F’s components only communicate in defined ways. Combined, these strategies make 75F easy to integrate, maintain, test, and scale efficient automation and the digital twin.

Let’s return to the aforementioned example of a 75F customer in Singapore. Using existing building equipment and air handlers, the customer could bring the zone-level automation and air quality readings of each room into a real-time or near real-time model of the building using an open-source web framework accessible via APIs. Because this data is delivered by 75F’s IoT based BMS pre-tagged, it does not require custom programming to determine which room, office, VAV unit, sensor, or device is delivering the data, and because 75F uses a common Haystack ontology, the data can be cleanly incorporated into a proprietary custom software package.

In this case, instead of using a digital twin to analyze or troubleshoot building data, a digital twin can be used as a platform to future-proof a building, standardizing information for rapid deployment of custom software and enabling multiple siloed building systems to share data in a single place and work together. For this customer, air conditioning, ventilation, indoor air-quality, and more could be automated and controlled with 75F’s integrated digital twin, lowering energy costs and improving usability. Room and visitor access management could be automated through standalone tools with parallel data architecture for portfolio-wide integration, even with different systems and equipment in each building, and different services providers for each solution.

With an IoT-based building automation system from 75F, the customer could achieve their energy efficiency goals in cooling and ventilation while also using 75F’s integrated digital twin as a platform to bring data into a lightweight custom solution that worked across systems. As an added bonus, 75F’s IoT based system allowed not just indoor air quality monitoring, but automatic indoor air quality management as well.

Digital twins and the future of smart cities

Designers and architects are increasingly seeing the value of holistic, integrated technology design. In the future, buildings with differing equipment profiles and protocols, specifications and networks, mechanical and technology contractors, hardware and software stacks, and data models and overlays will be replaced with IoT-enabled buildings connected to powerful digital twins.

Future upgrades and integrations will be accomplished by built-in tools and dashboards enhanced with seamless and scalable, cloud-based overlays and customization. Building engineers and operating teams will be less reliant on any single vendor and efficient processes and performance will be driven by a more cooperative ecosystem of service providers. Finally, all of this will be driven by a centralized and standardized data architecture using a digital twin to contextually link data points with any other data point in the space or in the portfolio, and optimized automatically by a modern and sophisticated, IoT-based building management system with a common user interface.