Mercedes-Benz

Download Case StudyChallenge:

Innovation, efficiency, and comfort are the three signature virtues that characterise every Mercedes-Benz automobile. The same principles extend to how they operate their offices, and MBRDI's (Mercedes-Benz Research & Development India) recently inaugurated state-of-the-art facility in Bangalore is a shining example.

Firm on its mission to nurture excellence, MBRDI dedicated a whole floor of this facility to Learning & Development and aptly called it "Gurukul." Comprising of training rooms, meeting rooms, quiet areas and even in-house banquet halls, Gurukul's design and build prioritizes occupant needs and experience.

MBRDI was seeking an automation solution that would enhance their occupant's experience further — a system that improves thermal (temperature and air quality) and visual (lighting) comfort, provides tailored occupant experiences and empowers the facilities team with visibility into their energy consumption and HVAC & Lighting systems as well as remote management capabilities. All this while making saving energy and improving the facility's carbon footprint.

Solution:

MBRDI conducted a thorough assessment of 75F's solution, comparing it to some of the most prominent players in the industry. 75F stood out from the pack as the only player that offers a vertically integrated solution (Hardware + Software + UI + Data Analytics + Services) and for providing unified HVAC, IBMS & Lighting Control & Automation capabilities. MBRDI also found 75F to be a better fit, both in terms of value and capabilities. Even finer details, such as 75F's aesthetically designed sensors that complement the facility's design and the intuitive graphic user interface that serves up insights and analytics to the FM team, contributed to 75F winning this project.

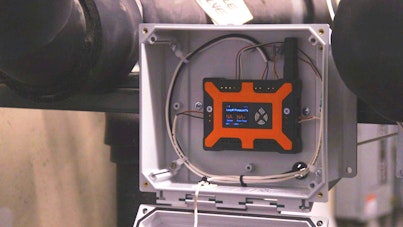

75F built a highly customized solution for MBRDI working closely with MBRDI's Project Management Consultants, Architects, Electrical Consultants and HVAC Design Consultants. Smart sensors were installed across the site, to collect real-time inputs for temperature, humidity, VOCs, CO2, movement, sound levels, LUX levels and even occupancy count for each zone. With millions of data points processed daily, 75F applies machine learning to predict daily challenges and proactively control HVAC and lighting systems for optimum comfort and efficiency.

Results:

75F's innovative system has brought incredible efficiency to MBRDI. With 75F system in place, the facility has been recording 25% savings on HVAC and lighting energy each month. Moreover, occupants enjoy a better work environment and increased productivity thanks to comfortable temperatures, improved air quality and better lighting.

Occupants of the facility are empowered to tailor their zones for temperature and lighting, allowing for precise comfort at all times. Features such as scheduling, daylight harvesting and occupancy-based control have made the facility 'switch-free' and intuitive, resulting in better occupant experience.

The facilities team at MBRDI now spends lesser time responding to occupant complaints and is able to deploy those resources to other important tasks. They have also noticed a marked improvement in their operational efficiencies; as a result of quick Installation, zero downtime and no on-site IT infrastructure and maintenance costs. Facilisight has provided the team with insight and control over the HVAC & lighting system in the facility. They are now able to monitor and control energy usage in real-time remotely.

75F's self-optimizing, intuitive system echoes the same principles that MBRDI holds close: innovation, excellence and comfort. MBRDI set out with great plans for their new state-of-the-art R&D centre and 75F took it to the next level with its unified HVAC, lighting, iBMS, automation and energy management system.