Border Foods

Download Case StudyChallenge:

Border Foods, one of the largest Taco Bell franchisees in the nation, had been trying to solve a vexing problem in their restaurants for years.

Extreme heat imbalances in the kitchen led to a very hot working environment for employees in some areas, while other areas were sub-cooled. Cooks working the taco line in the summer took regular breaks in the walk-in cooler for relief. For Border Foods, employee retention, training and productivity were key business drivers.

In addition, the new bright and cheery décor meant lots of windows in the dining area that led to solar gain challenges that move with the sun throughout the day. Finally, Border Foods was experiencing issues maintaining positive pressure in their buildings, creating problems like difficult-to-open front doors.

Solution:

Border Foods tested the 75F Dynamic Airflow Balancing™ solution at their Taco Bell store in Richfield, MN. 75F installed internet-connected airflow balancing devices to solve the problem in the kitchen and dining areas.

By obtaining a live weather feed and collecting empirical data about everything going on inside and outside the building, the 75F cloud-based algorithm was able to rapidly learn and adjust the balance of airflow. This caused temperatures to become uniform throughout the day.

Equipment included two Central Control Units, 11 Zone Controllers and 19 Modulating Dampers that were all installed and commissioned in less than a day. 75F also added Outside Air Optimization and Building Pressure Control to create positive pressure in the dining space to diminish drafts and keep odors contained in the kitchen.

"We have employees and vendors telling us that they've never been in restaurants in our company that have been this comfortable."

Results:

Within 24 hours, the kitchen staff noticed immediate relief from the heat island in the center of the kitchen. Temperatures leveled out between the front and back of the kitchen to create a uniform, comfortable environment. The dining area also leveled out so that morning and evening diners did not have to choose between East and West facing tables.

"Our kitchen employees noticed an immediate improvement in temperature and comfort. We have never felt this good." — Naomi H. | Store Manager

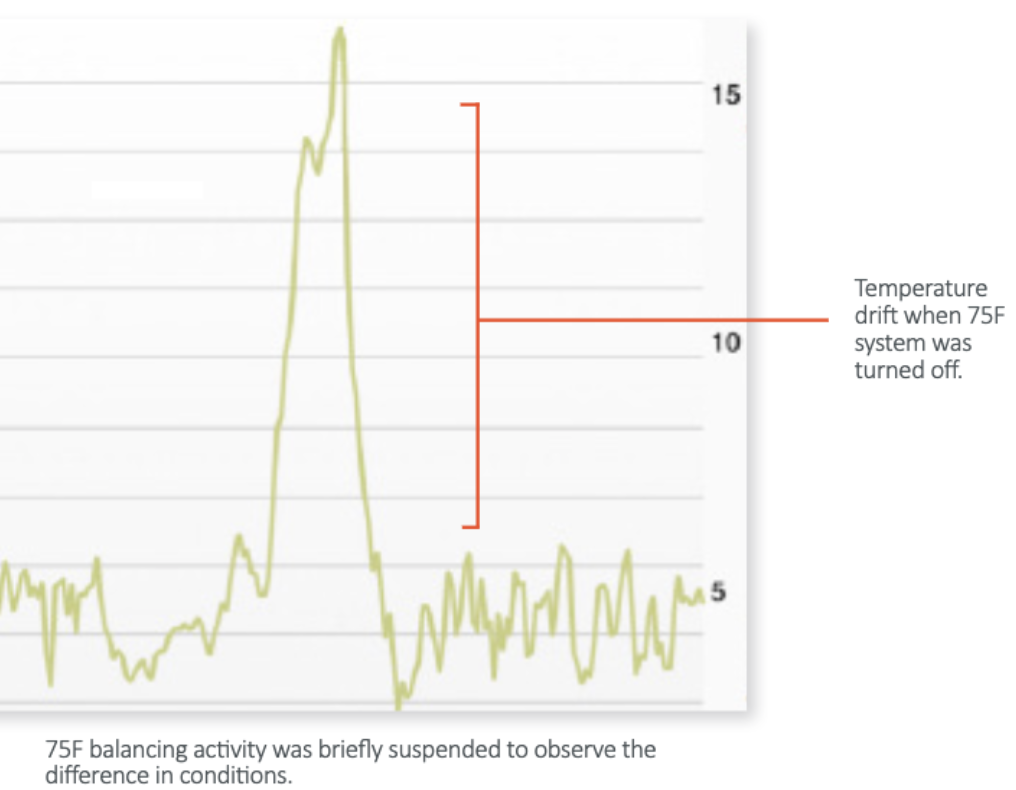

To prove the point, Border Foods authorized a short test where 75F balancing activity was briefly suspended so they could observe what conditions were like with the previous static balancing equipment. Within minutes, heat islands shot up in the kitchen. The imbalance rose 10 ̊F before the test was concluded.

Border Foods also noticed improvement in regards to pressure balance. Prior to 75F, Border Foods experienced a pressure reading of -0.19” WC (water columns), which caused problems opening doors. After 75F implemented Building Pressure Control, they maintained an ideal reading of 0.03” WC, which eliminated drafts.

Without the 75F system, Border Foods would have been commissioned to respond to the “typical” Minnesota winter, warming up the building whether or not the area was occupied. With the 75F solution, the system was able to take weather forecasts and pro-actively commission the building appropriately. Since installation, both staff and guests have enjoyed consistent comfort throughout the building.