Apple Valley Commons

Office solves operational challenges, saves 28% total building energy use

CHALLENGE:

Apple Valley Commons is a mixed-use office complex built in 1986 with 60,000 square feet and six floors. Current tenants are businesses ranging from dental clinics to law offices. Before installing 75F, employees and clients experienced daily disruption from extreme temperature imbalances in the building.

Despite outdoor temperatures consistently in the 80s and higher during Minnesota summers, occupants brought space heaters to their offices to keep warm. Electricity bills from 24/7 heat pump operation were so expensive, the building owner printed out a sign in the lobby requesting tenants turn off thermostats at night.

Meanwhile, temperatures in the elevator room on the roof skyrocketed. When it grew hot enough — 130 to 140 degrees — elevator equipment shut down. The building owner had maintenance workers on site three times a week to troubleshoot.

The building’s existing controls solution did not provide a front end for diagnostics or remote control. Building management sought a solution that could solve their temperature issues to improve occupant comfort while simultaneously lowering operational costs and increasing building visibility.

SOLUTION:

75F began the installation by setting up heat pump control with 11 Central Control Units and 53 Smart Stats. Installers pulled the associated data into 75F® Facilisight™ to better understand how the system was working. Next, 75F fabricated, programmed, and installed the 75F Grey Box, a central plant control panel with Tridium Niagara Framework.

In the overheating elevator room, 75F installed a HyperStat and a new actuator to better control the exhaust fan, which 75F discovered had not been working for years. The room now operates with a consistent 75-degree setpoint.

Throughout the installation, 75F ran into numerous building system problems. Because the building layout changed since its original design in 1986, ducts crossed into different zones — leaving some tenants unable to access their own thermostats because they were mounted in a different business suite. The building also contained dead wires that were never cleared from previous work. Importantly, 75F installers discovered that some heat pumps were not hooked up with fire lines, which would have been a serious safety hazard in the event of a fire. 75F rectified all these issues so the job site was clean, functional, and safe.

"When 75F came to the building, they used their brains. They're not just installing the controls — they solved the problems here. That's the real reason I hired 75F."

Results:

Building management’s primary hope in searching for new controls was to solve occupant comfort and building operational challenges due to temperature imbalance.

With corrected zone treatment and IoT-enabled control algorithms based on building data and the weather, Apple Valley Commons tenants no longer need space heaters to keep warm during the summer. The elevator room on the roof operates at a consistent 75 degrees and no longer shuts down, saving significant maintenance costs.

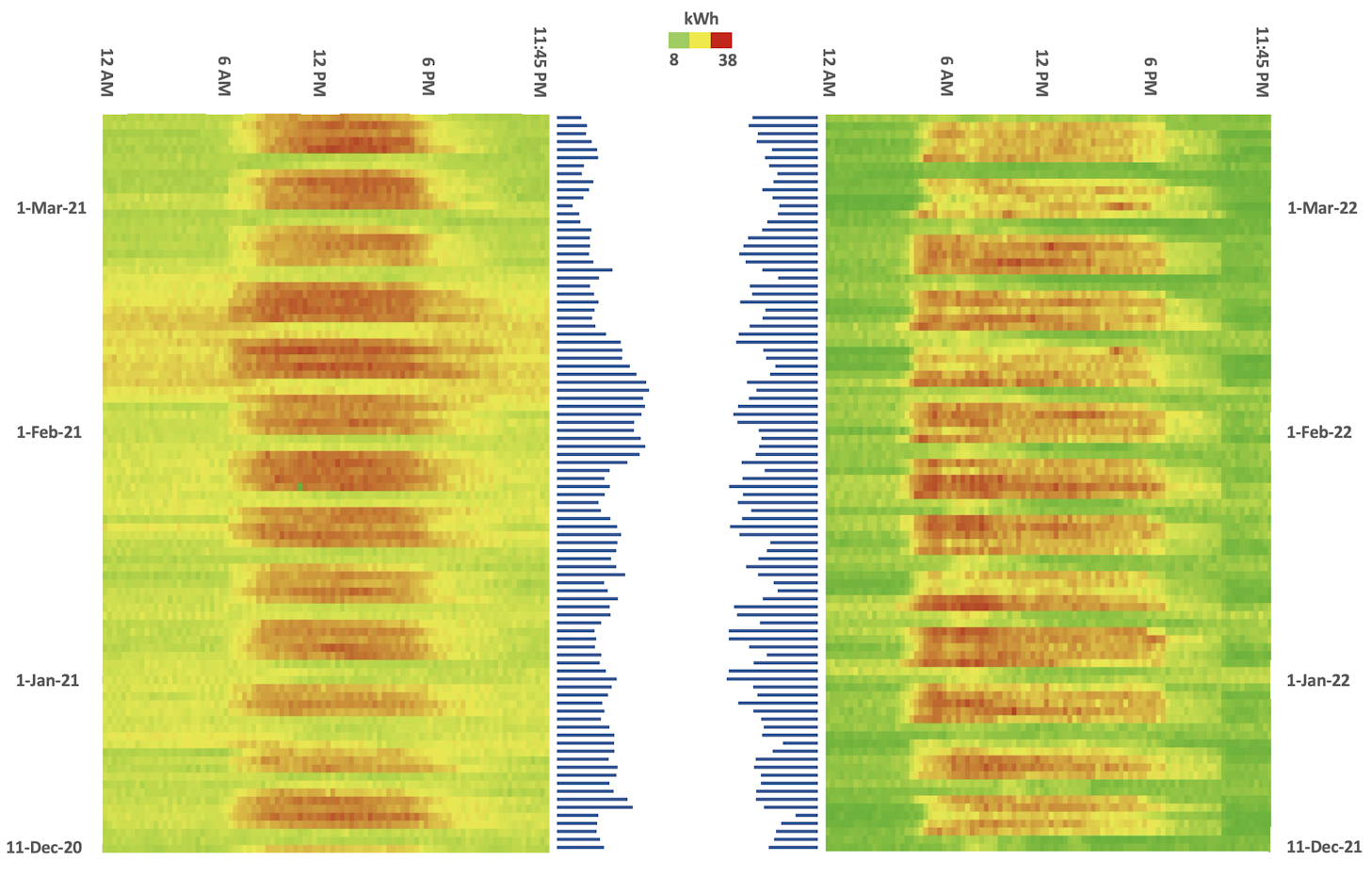

In tandem to occupant comfort, building management gained 28% total building energy savings (normalized for weather) and remote insight and control capabilities. Operators can easily check up on building, zone, and equipment data and make changes from wherever there’s Internet. Apple Valley Commons management were also grateful for the knowledgeable installation process, which unearthed and solved serious building problems.

At left: Apple Valley Commons energy use in 15-minute intervals from December 2020 to March 2021, before installing 75F. At right: Energy use in 15-minute intervals from December 2021 to March 2022, after installing 75F. At center: Heating degree day markers demonstrate outside temperatures for energy comparison, with longer bars indicating colder days. Data courtesy of Dakota Electric.

75F Design & Implementation Services

Grey Box Solution75F’s Design & Implementation Services come with Standard, Packaged, and Turnkey tiers for projects ranging from light commercial applications to custom, integrated solutions across portfolios.

Part of the Packaged tier, the Grey Box solution is a pre-wired and pre-assembled central plant control panel with a power supply and UL-certified Supervisory Plant Controller. It comes in four standard configurations for a wide range of building equipment and systems. It integrates central plant HVAC equipment to supervisory building systems, bringing industry-leading energy efficiency and powerful algorithms to commercial buildings of every size.